Tea making equipment

Tea making equipment

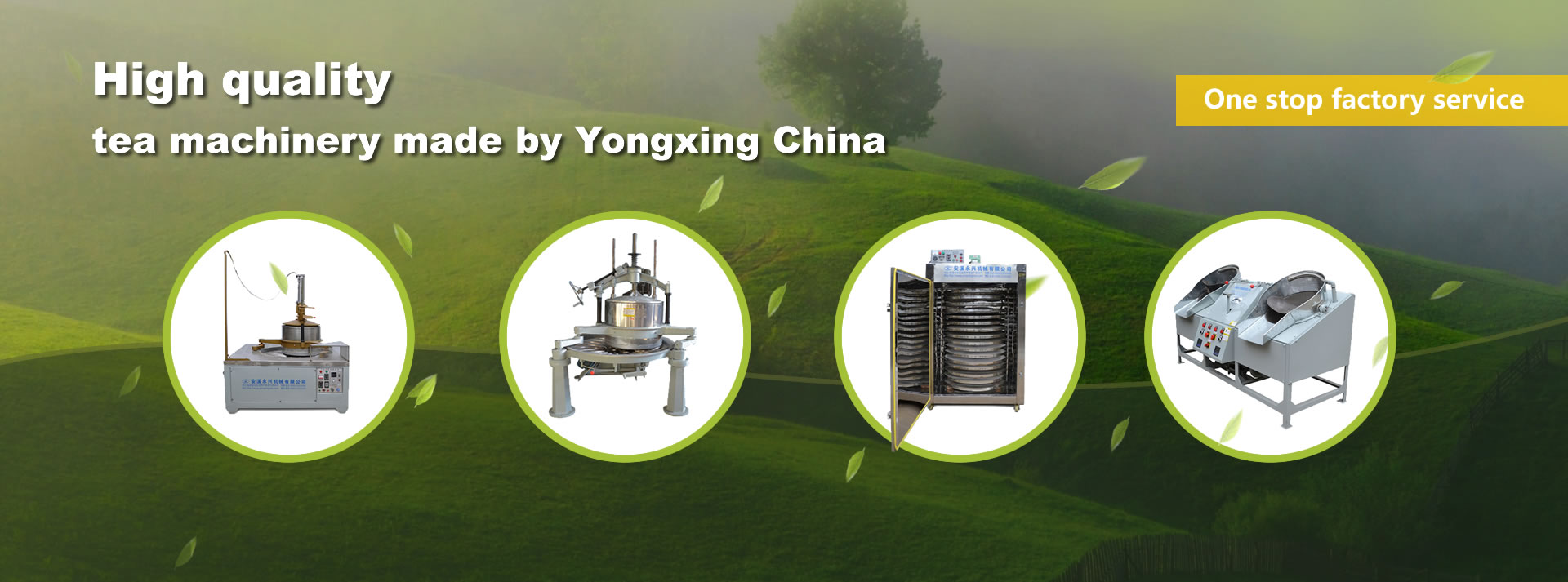

To start a business, you need to carefully prepare and install the equipment. What you need:

Drying equipment - drum type or troughs with heating and ventilation.

Dryers - so as not to be affected by weather conditions.

Rollers - to replace manual rolling, the simplest roller costs from 800 USD.

Fermentation chambers - control the fermentation process. But this is not necessary, a room sufficiently adapted for this purpose and a knowledgeable specialist.

Sorting equipment - for raw materials and for finished products.

Mixers.

Filling and packaging equipment - for packaging finished products.

Tea press.

Crusher.

Other auxiliary equipment - for tedding, tipping, blending.

When calculating the cost, the simplest production line will cost about 10000 USD. Currently, you can purchase a ready-made automatic line for the production of tea at any stage. If you take used equipment, then it will cost several times cheaper than new equipment and will allow you to master the business from scratch, make it profitable.

Room requirements

There are certain requirements for tea production facilities:

It must comply with all SES standards.

Have several separate rooms:

warehouse for raw materials;

warehouse for finished products;

manufacturing facility;

rooms for staff.

Be equipped with electricity and water supply.

The production area must also meet technological requirements, mainly maintaining high relative humidity and a certain temperature (22-26 ° C). The fermentation room should face north to avoid direct exposure to the sun. In terms of area, it is necessary to provide for a fairly large room to accommodate equipment, to have space for shelving where fermentation takes place.

Staff

Your mini-production needs 5-6 people:

director - function of management and marketing of products;

technologist - the function of monitoring all stages of production and product quality;

3-4 workers - to work on the line.