Description

There are many trays to place bamboo sieves. Freshly picked fresh leaves put on bamboo sieves for subsequent sunning or withering. Withering can be either an extended process or something brief. Either way, it is one of the defining elements within tea's process. Withering (like drying) needs attention to detail.

Thin careful layering ensures each leaf, stem, and batch is consistent. Racks of leaves are carefully rotated to ensure each layer receives proper airflow. The withering process reduces the water content of the leaves by as much as half.

Product Function: |

Tea leaf wither rack usually used for processing black tea, green tea. oolong tea, ctc tea, flower tea and herbal tea etc.

After plucking, all the tea leaves are gathered at bamboo sieves and sent for the withering process. For example, tea leaves were spread on a perforated rack for 14-18 hours or till the moisture content comes down to 50%

Product Features |

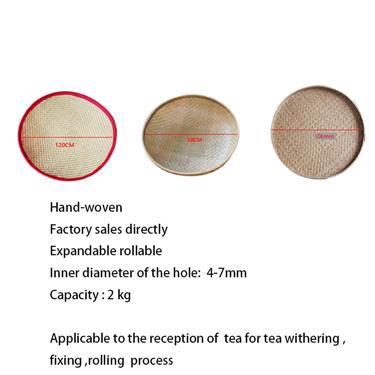

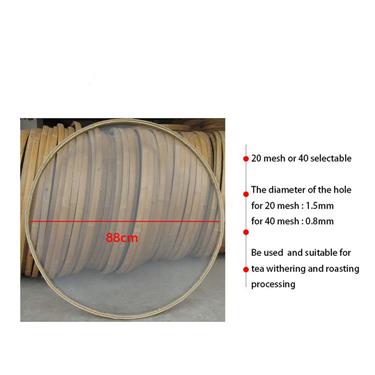

1. Tea leaf wither rack is rugged and durable, the bottom of the sieve tray is ventilated with mesh and good ventilation;

2. There are bamboo sieve and stainless steel sieve for your choice

3. Bamboo sieve with cheap price, withering speed is fast.

4. Stainless steel sieve with food grade material, it makes tea leaf more cleaner.

How to wither tea leaves |

Freshly picked leaves are set out to wither. The tea leaves would sit for a while and then we would need to go back and "hand fluff the tea" 3 times; each time with a little more intensity. You need to maneuver your basket so all the tea leaves are towards the center.

Once the tea leaves are in the middle you then go back and forth with your hands to fluff. The withering process reduces the water content of the leaves by as much as half. Without withering, subsequent heating steps would produce something akin to cooked vegetables, rather than dried tea leaves.

Specification |

Model | Version A /B/C/D/E/F/G/H |

Griddle Plate diameter | 580-1200 mm |

Layers | 16& 20 layers |

Layer height | 120 mm |

Griddle Plate materials | bamboo type: Version A /B/C/D/E/F |

stainless steel type: Version G/H | |

Rack materials | Iron with the anti-corrosive treatment |

About product installation, training and after-sales service |

Most products can be installed and trained through online video and text mode. If special products need to be installed on site, we will arrange technicians to install and debug on site.

Our Advantages |

Our factory is Anxi Yongxing Tea Machinery Co., Ltd.. It's a tea processing machinery enterprise integrated with design, manufacture and sale. The factory has more than 30 years of experience in producing tea equipment.

Reasonable prices and reliable quality. In tea processing industry, we have won the Innovation Achievements Gold Award of Employees from Both Sides of the Taiwan Straits, and Several National Patent Certificates.

We always feel that all success of our company is directly related to the quality of the products we offer. They meet the highest quality requirements as stipulated in ISO9001, ISO14000:14001 SGS guidelines and our stringent quality control system.

Our Services |

1, We are professional on machine producing.

2, If have any questions during machine operation and delivery ,our sales manager and technical personnel will give you the best advice

3, If you want to know the machine operation please contact with us and we will send you video and detailed information.

4, If there is any questions, please do not hesitate to contact us in time and tell us what happened ,our technical personnel will give you the solution .

5, We will choose the most suitable machine with our professional knowledge.

Why us ? |

1.Quality guarantee

2.One-stop service without any outsourcing

3.Best Materials selection

4.On time delivery

5.Professional export for years