How to operate tea winnowing sorting machine ?

Quanzhou Famous Trademark

Executive standard: JB/T7321-2007

User's manual

Anxi Yongxing Machinery Co., Ltd.

Table of Contents

Overview

Intended use of the machine

Safety Precautions

First, the safety warning sign

Second, security matters

Chapter 1 Product Introduction

Chapter II Product Example Picture and Main Technical Parameters

Chapter III Product Structure Schematic and Working Principles

Chapter IV Use and Operation Transportation, Installation and Adjustment

Chapter V Maintenance and Maintenance

Chapter VI Troubleshooting and Troubleshooting

Chapter VII Main Parts List

Overview:

This instruction manual is an integral part of the machine and is recommended for suppliers of new or second mobile phones.

All relevant documents should be kept to prove that this instruction manual is provided to the user at the same time as the machine.

The intended use of the machine:

The products mentioned in this instruction manual are only used for various points in the initial or refining process.

Screening operations for other operations are contrary to the intended use of the product. Strictly observe the manufacturer

The prescribed use, maintenance and repair conditions, as well as the basic requirements for the intended use.

The products mentioned in this instruction manual can only be familiar with the characteristics of the machine and have the relevant safety.

Operation, maintenance and repair of personnel with full operational knowledge.

At all times, you must comply with rules and other safety regulations and regulations that prevent accidents.

then.

Reliable machine due to unauthorized modification of the products mentioned in this instruction manual

The manufacturer is not responsible for reduced performance, machine damage or personal injury.

Safety Precautions

First, the safety warning sign

In this instruction manual, safety warning signs indicate important safety information. When you see the following symbols,

Be alert to possible injuries, read the information in the symbols below and tell other operators.

E F 4 0 Tea air sorter warning sign

Attached to the protective cover

Stick to the eye-catching part of the machine

Attached to the grounding post (bolt)

Second, for the safety of you and others, please pay attention to the following safety issues:

1. Check the quantity of parts according to the list and keep them in a safe place to avoid loss.

2. Users must read this manual carefully before purchasing, installing and using the products of the company, so as to avoid

An error has occurred.

3. Carefully implement the regulations and requirements for the use and maintenance of this equipment. Special training for new players, no

A qualified operator must not operate this machine.

4. Check that the power cord is intact and the power cord must not be damaged. The power supply used in the product is three-phase four-wire

System, electric heat source voltage 220V, motor 380V, wire diameter of installation wiring should be ≥2.5mm2, wiring should be

Electrical work.

5. Before powering on, you must first connect the electric shock protection device and the grounding wire, and the grounding wire is firm and reliable.

Safe electric safety, the grounding wire can be fixed at any threaded joint of the machine base.

6. Before starting the machine, make sure that there is no debris in the machine, flexible and reliable, no abnormal sound, to ensure the normal operation of the equipment.

The operating environment should be well ventilated, the tea machine is more than 500mm away from the wall, and the machine is banned from flammable and explosive.

Items and odorous items.

7. Operators are not allowed to wear loose clothes that are easily caught in moving parts. Long hair wearers must wear safety.

cap. The operator must not leave the machine while the equipment is running, especially pay attention to the moving parts, which will collide with the human body and wrap

Around the arm, clothing, etc., very dangerous. Do not continue to operate the machine under fatigue or drink conditions, non-operator

Members must not use the equipment.

8. Non-operators and children should not be near the machine when the machine is turning.

9. During the operation of the machine, jamming, collision and abnormal sounds occur, such as failure to judge the fault.

For sources or faults that cannot be easily handled, the power should be turned off before checking. Never run on the machine

State the fault to avoid personal safety. In the event of a power outage, be sure to turn off the power immediately.

10. During normal shutdown, first press the vibrating conveyor to stop the switch, then press the fan to stop the switch, and finally

cut the power.

11. The equipment used should have a dedicated person responsible for operation, inspection and maintenance. When checking and maintaining, be sure to be timely

cut the power.

12. In case of thunderstorms, do not use, you must cut off the power supply to prevent lightning damage to electrical components and people.

An accident.

13. Turn off the power (blade) after the end of the operation to avoid a fire.

14. Always check the joints of the machine and the machine entry line for scorch. Electrical systems must be constantly dimensioned

Care, maintenance, and found that the wire is damaged and aging should be replaced immediately.

15. Except for repairs, the safety cover must not be removed at will to avoid injury.

16. Regularly check that the fasteners are reliable, tighten the loose fasteners, tighten the belt or tighten

The firmware, sliding sleeve or guide rail should be replaced when worn.

Chapter 1 Product Introduction

The tea air sorting machine is one of the special machinery for tea refining. After the sieved tea leaves, press it lightly through the machine

Grading and other grades, suitable for the middle-grade sieve tea grade of refined black tea, the tea grade of the upper section of green tea is graded.

The change of fan speed and the change of fan inlet diameter can also be used in refined black tea, the lower sieve and green tea.

In the middle, the upper part of the sieve tea grade.

Chapter II Product Example Picture and Main Technical Parameters

1, product example picture

EF40 tea winnowing sorting machine (conventional stand-alone machine)

EF40 tea winnowing sorting machine (supporting production line)

2, the main technical parameters

EF40 tea winnowing sorting machine (conventional stand-alone machine)

Project | Unit of Measure | EF40 Wind -feeding tea Air selection machine | |

Number of Changeable gears | gear | 5 | |

Production capacity | kg/h | 250-400 | |

WinnowingMachine | Equipped Motors | YDW0.8-6 | |

Voltage | V | 380 | |

Power | KW | 0.8 | |

Full pressure | Pa | 300-340 | |

Flow | M3 /h | 4250-5360 | |

Noise | Db | Approx . 72 | |

Dimensions (length ×width × height) | Mm | 3630x565x1685 | |

EF40 tea Wind selection machine (supporting production line)

Project | Unit of Measure | EF40 Wind -feeding tea Air selection machine | |

Number of Changeable gears | gear | 5 | |

Production capacity | kg/h | 250-400 | |

WinnowingMachine | Equipped Motors | YDW0.8-6 | |

Voltage | V | 380 | |

Power | KW | 0.8 | |

Full pressure | Pa | 300-340 | |

Flow | M3 /h | 4250-5360 | |

Noise | Db | Approx . 72 | |

Dimensions (length ×width × height) | Mm | 4348x560x2688 | |

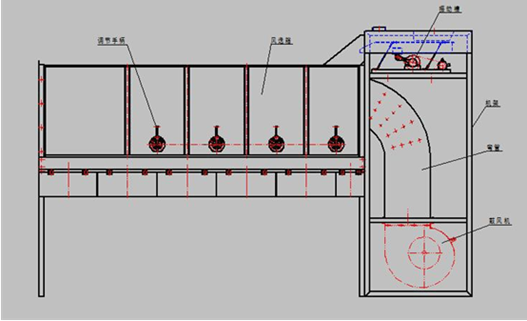

Chapter III Product Structure Schematic and Working Principles

Product structure diagram

The schematic is EF40 tea winnowing sorting machine

working principle

The tea leaves that have been sieved by round sieve and shake sieve have become sieve tea with the same length, thickness and shape.

However, due to the different degrees of tenderness of the tea leaves, the weights are different, and the size of the windward side is different.

The tender, tight, and heavy tea leaves are small in the wind, and under the action of the wind, the tea leaves are relatively close, and the bones are light.

The yellow sheet and the like have a large windward surface, and they fall farther with the wind under the action of the wind. Thus dividing at different distances

Leaving different quality tea leaves, achieving the same level of weight and consistency. At the same time, sand, stone, metal, etc.

The inclusions are separated from it.

The main engine consists of two main components: the air supply device and the air selection box.

The air supply device is composed of a blower, a blade regulator, an elbow, a frame, and the like. Blower impeller speed

Through the inverter adjustment, it can be arbitrarily changed within the range of 800-1200r/min. The air inlets on both sides of the blower are equipped with leaves

The chip regulator can change the size of the air inlet arbitrarily, so as to change the air volume and wind pressure to adapt to different types.

Tea and different process requirements.

The air box is connected to the air supply device. The tea leaves are sent to the air box through the vibrating conveyor, and the vibrating conveyor can be rooted.

According to the size of the tea when adjusting the switch, the knob changes the amplitude to control the tea speed. After the tea enters the air box, it is due to the air.

Involved in the various tea breaks, each gear has an adjustment handle to change the angle of the adjustment plate, which can change the light tea taken in each bucket.

Heavy, so that different levels of tea are sorted. The air outlet is equipped with a damper to adjust the air volume and wind in the bellows.

Pressure.

Chapter IV Use and Operation, Transportation, Installation and Adjustment

1, use and operation

1.1, preparation before starting the machine

(1) Remove the remaining tools and debris from the machine and clean the dust at the air inlet of the fan (every shift must be checked).

(2) Check the bolts, screws and pins of the components, especially the keys and nuts of the fan.

Fixed to ensure safety.

(3) Check whether the lubricating oil of the fan bearing, conveyor belt transmission and other lubrication points are in accordance with the regulations.

Add enough.

(4), pull the belt by hand to check whether the fan is working properly.

(5) Check whether the electrical equipment is safe and reliable, then test run, check the fan and conveyor belt steering

Nothing is normal.

1.2, the sequence of operations

(1) Start the main engine running, and the fan air inlet handle is placed in the fully open position.

(2) Adjust the vibration intensity of the vibrating conveyor to moderate.

(3) Start the conveyor belt to transport tea leaves.

(4), open the tea door with tea bucket, adjust to a certain degree of opening according to the process requirements, control the tea flow moderately,

Fine-tuning the size of the air inlet of the fan and the angle of inclination of the tea board in the half-time tea, so that the tea clarity is the best.

2. Transportation, installation and adjustment

(1) When the machine is transported, it is required to be placed stably and cannot be twisted. Measures such as anti-collision, moisture-proof and anti-squeeze should be provided.

Do not place sharp and heavy objects on the pot to avoid damage to the pot.

(2), the ground is required to be level.

(3), must carefully check whether the voltage of the power supply is consistent with the voltage of the appliance selected by the product, and connect

Proper line and electric shock protector to protect your personal and equipment safety.

(4) Remove the debris from the surface of the machine and wipe it off with a cloth.

(5) Check whether the fasteners are reliable and tighten the loose fasteners.

(6), turn on the power to start the machine, for 0.5 hours of empty operation, no jamming, collision and abnormal sound

The phenomenon is loud.

Chapter V Maintenance and Maintenance

(1) During the working process, the machine should pay attention to the heat of the fan and the bearing.

Fan temperature rise must not exceed 65

The maximum temperature of rolling bearings must not exceed 70

The maximum temperature of the sliding bearing does not exceed 65

If there is overheating or abnormal impact, noise, etc., it should be stopped and checked in time to eliminate the fault.

jobs.

(2) After the machine has been put on hold for a long time, it must be inspected and tested before starting, and the lubricating oil at each bearing should be replaced.

fat.

(3) Regularly add oil to each lubrication point to ensure normal operation (the rubber plate bearing parts of each gear are generally not allowed to be refueled to avoid

Contaminated tea leaves, but when there is rust or stuck, it is allowed to add a small amount of grease to make it flexible.)

(4), must strictly abide by the equipment maintenance system, carry out maintenance on time, the machine must be repaired once a year, inspecting

The parts should be cleaned during repair and the damage of the consumables determined to be repaired or replaced.

Chapter VI Troubleshooting and Troubleshooting

Common troubleshooting | Repair methods |

No wind | Check if the power supply is out of phase, or the power supply is reversed.

|

wind return seriously | Check the wind and check if the air damper is closed.

|

Chapter VII Main Parts List

Model | serial number | part name

|

Tea winnowing sorting machine

| 1 | blower |

2 | Bent pipe | |

3 | rack | |

4 | vibration tank | |

5 | wind box | |

6 | adjustment handle |